HYPROTEC provides a full range of services in the supply, commissioning, calibration, certification, and verification of laboratory equipment and measuring instruments, whether standalone or part of complex devices. We perform annual maintenance, diagnostics, and repair of both warranty and post-warranty laboratory equipment of Russian and foreign manufacture. We also carry out commissioning of new and pre-owned laboratory equipment, including personnel training.

The HYPROTEC team has extensive experience and high qualifications, applying international standards and methodologies to ensure service quality. This guarantees reliable, safe, and long-term operation of laboratory equipment. Our specialists regularly attend training courses at manufacturers’ production facilities in the USA, China, and Russia, which allows us to solve tasks of any complexity accurately and promptly.

After commissioning, laboratory equipment requires periodic inspection and servicing. Timely maintenance ensures long-term, uninterrupted operation and compliance with operational manuals and procedures. Scheduled technical maintenance helps identify and eliminate minor defects and hidden malfunctions, thereby extending the equipment’s service life and avoiding costly repairs or replacements in the future. Reliable, continuous operation is only possible through regular and professional maintenance.

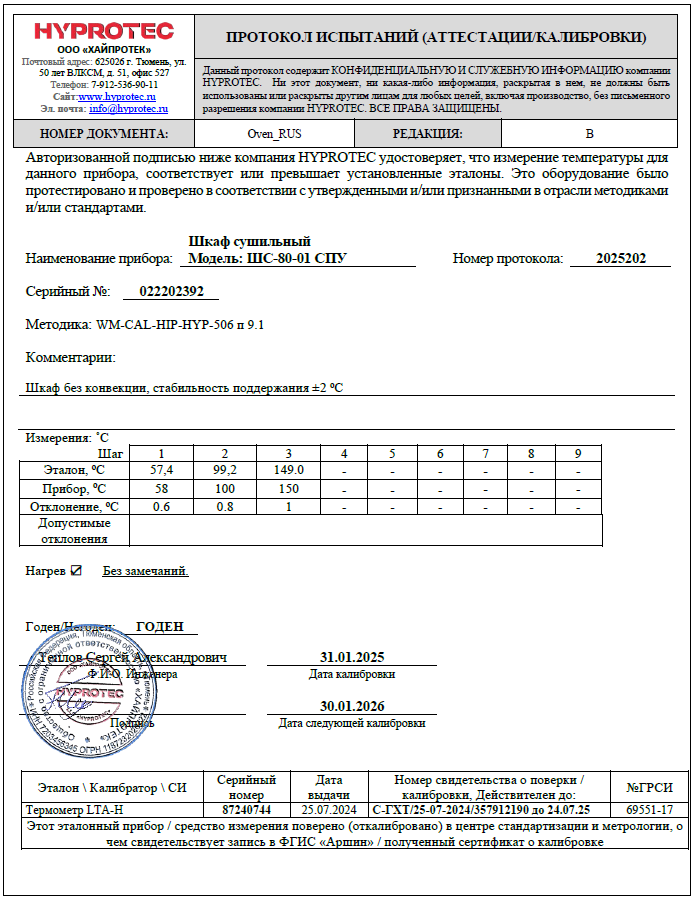

High measurement accuracy can only be achieved through regular calibrations and certifications. We can adjust and fine-tune the equipment according to the manufacturer’s manual, verifying its performance against technical and metrological documentation. During calibration, testing, or certification, our Service Center uses reference standards, certified reference materials (CRM), manufacturer reference samples, and approved-type standards. Work is carried out in strict accordance with the manufacturer’s documentation and measurement methodologies. During servicing, we perform a full inspection, cleaning (including opening the housing and seals), adjustment, lubrication, and alignment of electrical and mechanical assemblies.

Upon completion, the client receives a technical report on the equipment condition, recommendations for part replacement, and an official test, certification, or calibration certificate.