Modern challenges are related not only to achieving technical goals, but also to continuous staff training. Our instructors share their experience and current practices after completing training in international schools (HAL, BH, SLB).

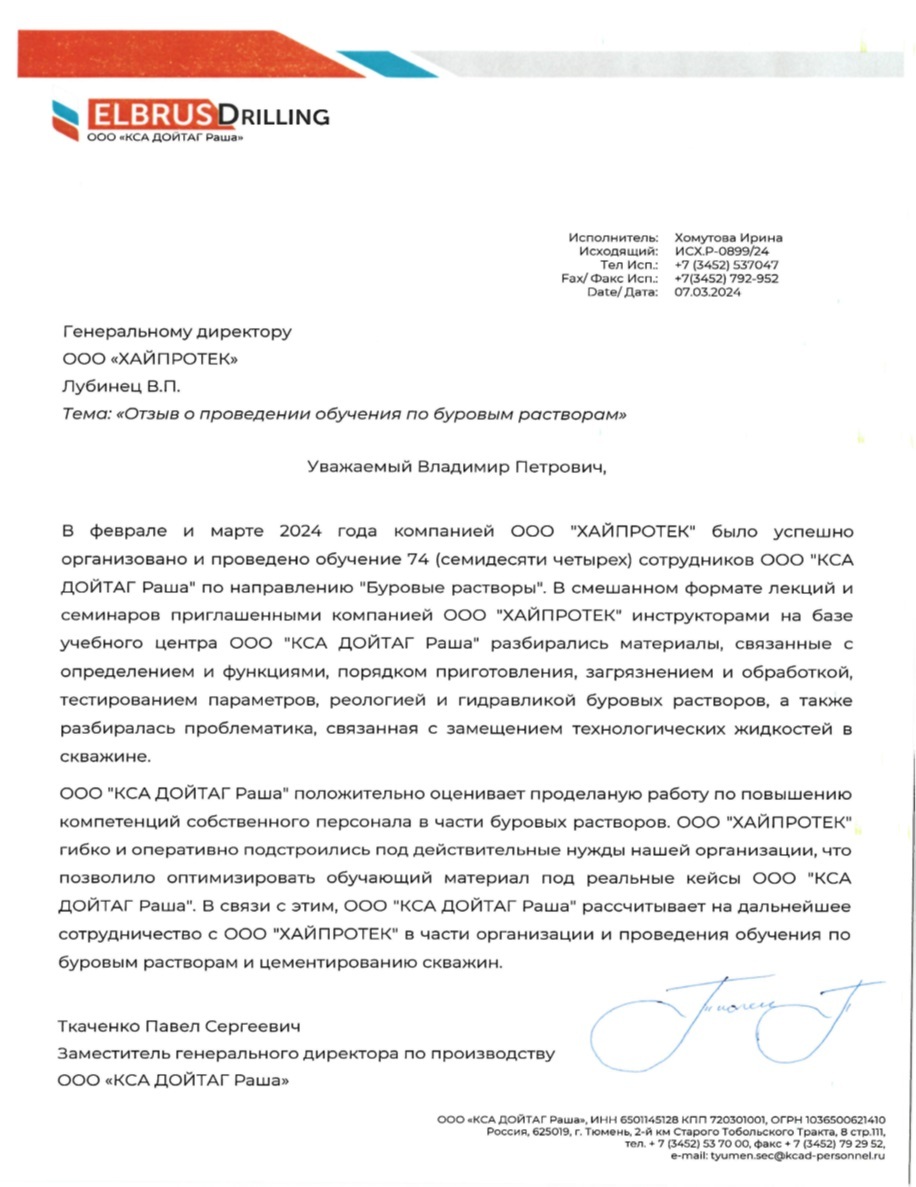

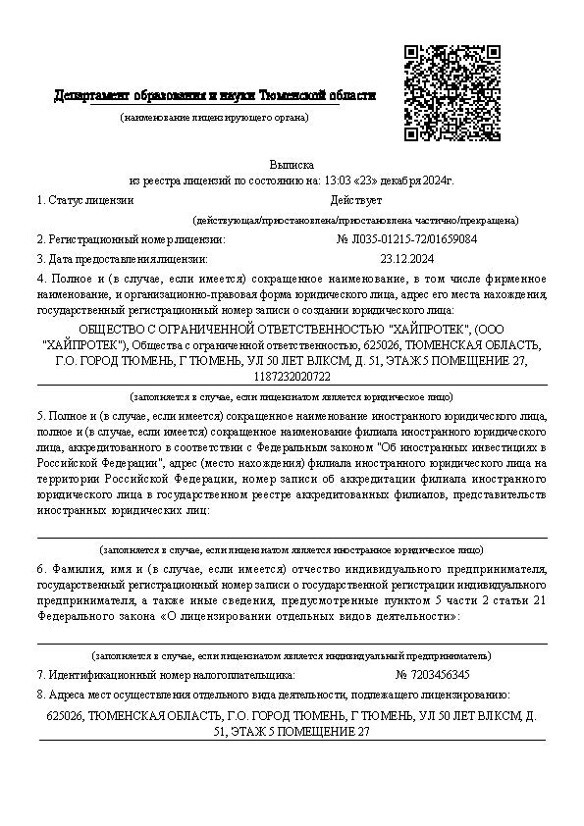

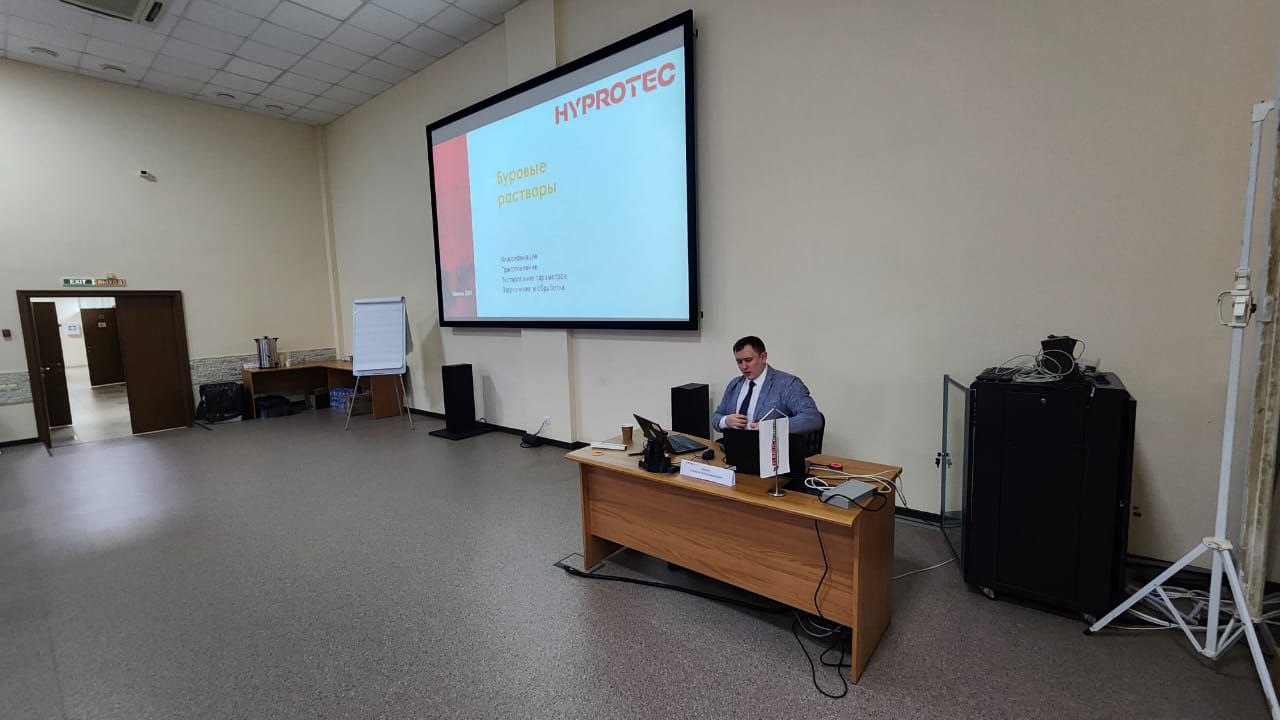

We conduct on-site and field training sessions at the client’s facilities. Programs are tailored to specific needs, and all results are officially documented.

At the NTC base in Novy Urengoy and at the Customer’s facilities:

- Assessment of current knowledge and competencies.

- Laboratory technician training: from basic to advanced level.

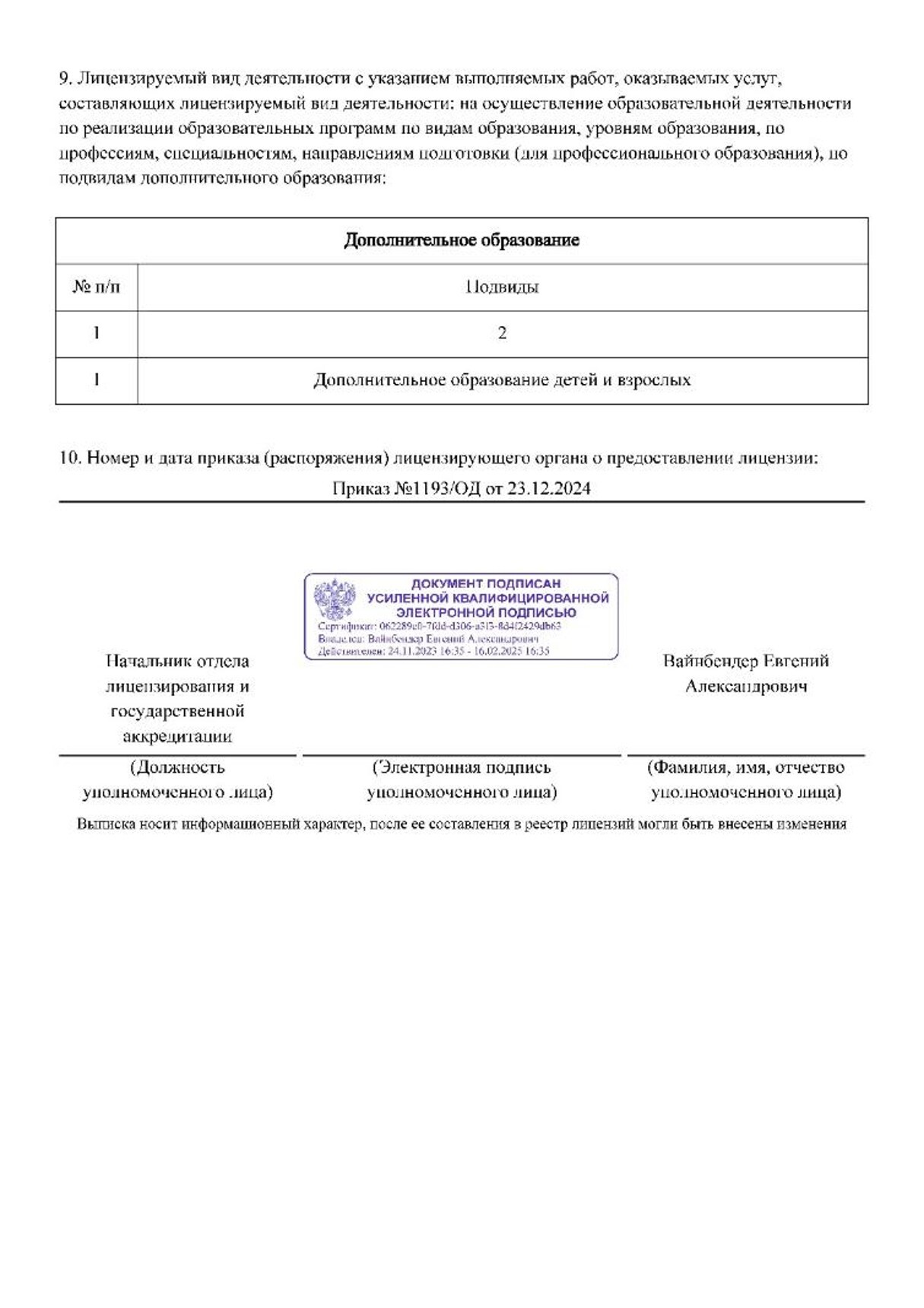

- Interim and final testing.

- Knowledge confirmation and certification.